MPO patch cord customized solutions

Number of the fiber: 8/12/16/24/48/72 cores in multiple configurations

Low insertion loss: ≤0.35dB

High durability: ≥1000 plug-in cycles

Compatibility: compliant with IEC-61754-7 and TIA-604-5 standards

Temperature range: -40°C to +85°C

OM3 MPO JUMPER

OM4 MPO JUMPER

OM5 MPO JUMPER

OS2 MPO JUMPER

Standard MPO Connector Series

High-density MPO+ Ultra-density Series

Scale data center capacity with our MPO+ series: ultra-high-density 96/144/288-core MPO connectors fully compatible with standard MPOs. Achieve a 40% boost in rack space utilization and streamline network expansion.

Rugged MPO Series

Customized MPO Solutions

Comprehensive MPO customization services: special fiber-counts, hybrid connectors, enhanced dust-/water-resistance, and broad cable compatibility—enabling system integrators to solve unique connectivity challenges in critical projects.

Customization options

Professional customization service, can optimize parameter design according to specific application environment

Special core count configuration

Non-standard configurations such as 16/32/48 cores

Hybrid fiber

Combining different types of fibers in a single connector

Special polarization requirements

Non-standard key configuration

Reinforced housing material

Metal/special engineering plastics

Special environmental adaptation

High temperature resistance/corrosion resistance/radiation resistance

Customized marking and laser engraving

Customer logo/tracking code/Compatible with customer’s existing systems

Phase 1: Demand Assessment and Design

Begin with a network assessment—inventory existing equipment, link lengths, and performance requirements. Our team analyzes bandwidth growth trends and fiber infrastructure quality, then designs the optimal solution with precise model selection, compatibility tests, and defined performance parameters.

Phase 2: customization and testing

Craft custom MPO connection solutions—connector types, cable selection, wiring paths, and cabinet/patch-panel layouts—based on your evaluation. We prepare materials, perform factory pre-termination, and conduct rigorous testing to ensure each optical cable meets exact specifications.

Phase 3: Deployment and Verification

Implementation process:

As a professional MPO supplier, we provide a complete MPO fiber system implementation process to ensure that each project is completed smoothly and achieves the expected performance goals.

Integration capabilities

Seamlessly integrate MPO cabling with leading network equipment—Cisco, Huawei, H3C, Juniper—via dedicated adaptors. Migrate legacy LC/SC systems using hybrid panels and branch cables. Optimize data center layouts for airflow and rack density. Enable DCIM visibility with RFID tagging and support comprehensive MPO testing with industry-standard interfaces.

Global Technical Support

Wolon's products have been widely used in the three major domestic operators, radio and television systems, power systems, the military, government agencies and other enterprises. Wolon established a foreign trade division in 2014. Its products are exported to overseas markets such as Russia, the Middle East, Southeast Asia and India, and have won unanimous praise from customers.

Certification

Ready to Begin?

Contact our MPO experts for a custom assessment: we’ll review your network architecture, pinpoint bottlenecks, plan expansion needs, and deliver an MPO upgrade roadmap with ROI analysis ensuring a more efficient, reliable fiber infrastructure.

Implementation timeline:

Requirements analysis and design: 1 week

Material preparation and pre-termination: 1-2 weeks

On-site installation and testing: 2-3 days

Total time: 2-3 weeks

Requirements analysis and design: 2 weeks

Material preparation and pre-termination: 2-3 weeks

On-site installation and testing: 1-2 weeks

Total time: 5-7 weeks

Requirements analysis and design: 3-4 weeks

Material preparation and pre-termination: 4-6 weeks

On-site installation and testing: 2-4 weeks

Total time: 9-14 weeks

Quality and reliability

As a professional MPO supplier, we implement a strict full-process quality control system to ensure that each MPO product has excellent performance, reliability and durability:

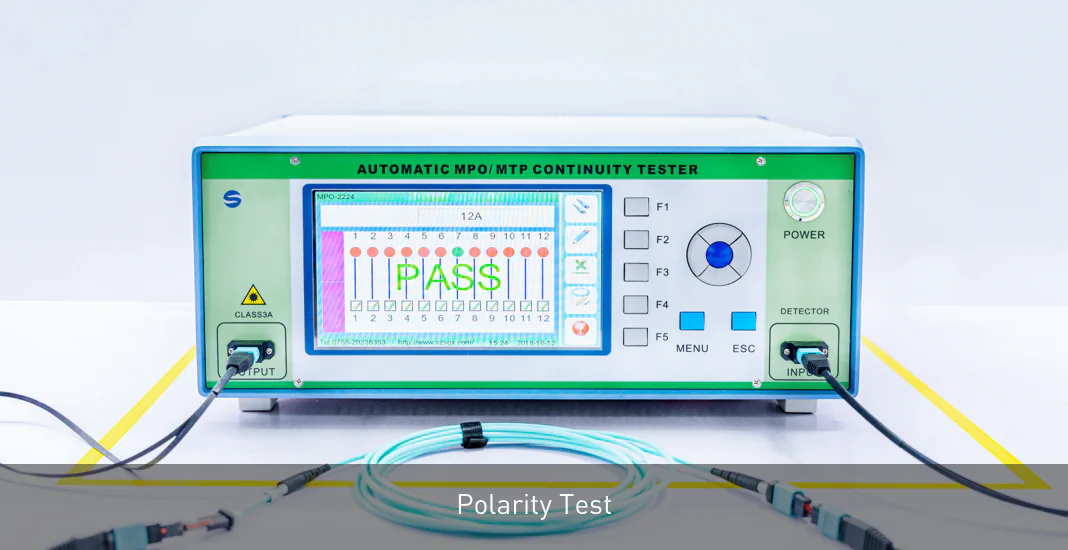

Our MPO connector production adopts a fully automated production line, combined with strict manual inspection points, to implement a “zero defect” quality policy. Each MPO connector production process includes the following key quality control links:

Raw material screening and control

All incoming materials are 100% inspected, including optical fiber, ceramic ferrule, spring and housing materials, to ensure they meet strict specifications.

The qualified rate must reach more than 99.9% before entering the production line. We have established a complete supplier rating system to ensure the long-term stability of the quality of core components.

Process quality control

16 key quality checkpoints are set during the production process, including real-time monitoring of parameters such as fiber alignment accuracy, bonding strength, and endface geometry.

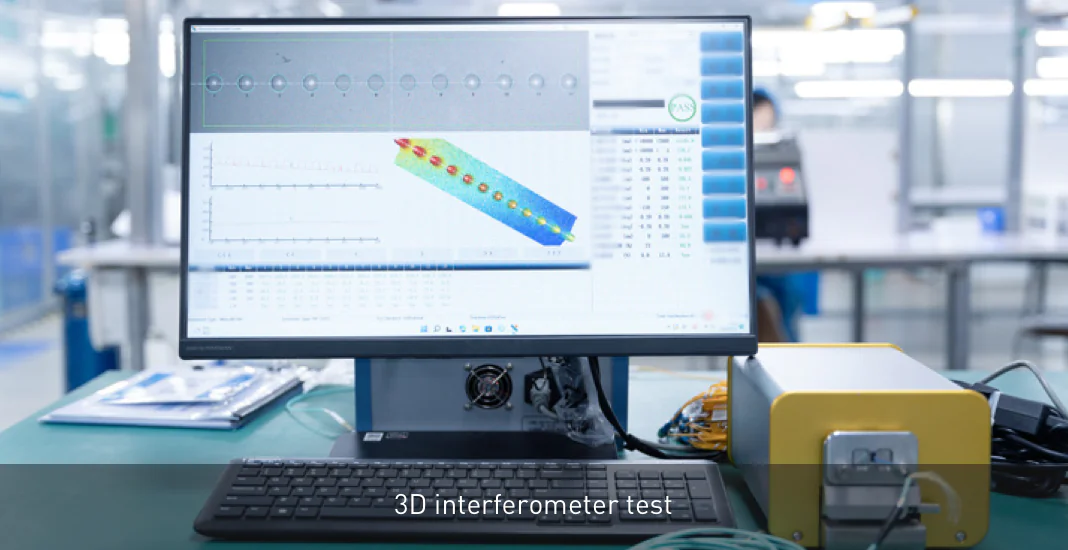

A high-precision interferometer is used to perform 16-zone analysis on each MPO endface to ensure that the endface curvature, endface angle, and surface finish are in optimal condition.

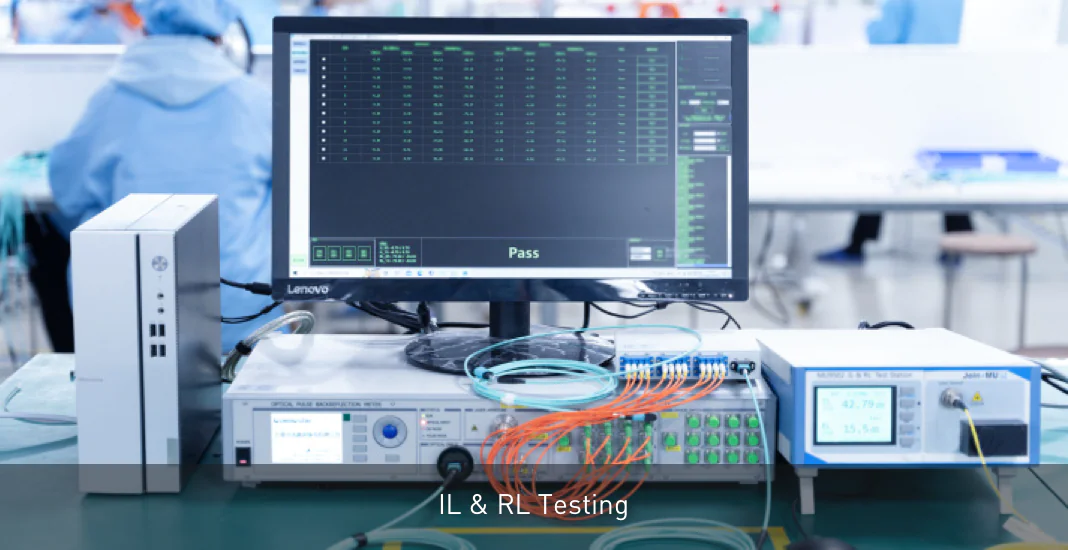

100% of products are tested for insertion loss and return loss to ensure that performance meets or exceeds specification requirements.

Final inspection

Each finished product undergoes a full parameter final inspection, including appearance, marking, packaging and integrity inspection.

Sampling is conducted for plug-in durability, tensile strength and temperature cycle tests to verify the mechanical reliability of the product.

Multi-point inspection of optical cable integrity, sheath bonding strength and bending performance.

Each MPO product has a unique batch code to achieve full life cycle quality traceability.

Modern state-of-the-art factory

offices worldwide

clean and intelligent workshop

Professional staff

Customer Cases

Our optical module solutions are implemented using a systematic process to ensure smooth deployment and optimal performance:

Large cloud service provider network upgrade

We helped a global cloud provider upgrade 4,000+ switches with 100G QSFP28 modules, boosting capacity 10×, cutting energy use 50%, and enabling 3–5 years of sustainable growth.

Telecom operators’ 5G fronthaul network construction

We deployed industrial-grade SFP28 25G fronthaul network modules, optimized for –40–85 °C and EMI resistance, achieving 3.5 Gbps/station, 99.999% link reliability, supporting dense 5G cells, gearing future expansion, and cutting costs 30%.

Financial institution data center interconnection

We tailored 100G DWDM modules with encrypted transmission and advanced DSP, reducing latency below 10 µs. Our solution achieved <1 ms cross-site sync, simplified architecture, and cut O\&M complexity by 40%.

Why Our Clients Love Us

We not only provide high-performance optical module products, but also provide complete optical interconnect solutions. Through industry-leading customization capabilities, strict quality control and full life cycle support services, we help customers build more reliable, efficient and scalable network infrastructure, reduce total cost of ownership and accelerate business innovation.

Procurement Process

We provide a flexible and efficient procurement process to meet the needs of different customers:

Standard product procurement

Submit an inquiry: Submit product requirements through the official website form, email or phone

Get a quote: The sales team will provide a detailed quotation within 24 hours

Confirm the order: Submit a formal order after confirming the configuration, price and delivery time

Payment processing: Support multiple payment methods, including letters of credit, wire transfers and corporate checks

Order tracking: Track order status in real time through the customer portal

Product delivery: Ship according to the agreed method and provide logistics tracking information

Customized product procurement

Demand consultation: The technical team assists in clarifying customized requirements and technical specifications

Feasibility assessment: The engineering team evaluates the customized solution and provides implementation suggestions

Sample development: Develop customized samples and provide testing support

Sample confirmation: Customers test and confirm that the sample performance meets the requirements

Mass production: Arrange mass production and conduct strict quality control

Delivery and support: Product delivery and provide installation guidance and technical support

Frequently Asked Questions

Find quick answers to the most common questions about our services and solutions.

How do I determine which type of optical module I need?

There are several key factors to consider when choosing a suitable optical module: network device interface type (SFP/SFP+/QSFP, etc.), required transmission rate (1G/10G/25G/100G, etc.), transmission distance and fiber type (single mode/multimode). We provide free network assessment services to help you determine the most suitable optical module configuration.

How do you ensure the compatibility of your company's optical modules with original equipment?

All of our optical modules have passed strict compatibility tests to ensure 100% compatibility with mainstream equipment manufacturers. We maintain a real-time updated compatibility database and regularly verify new equipment and firmware versions. Each batch of products is functionally verified in the actual equipment environment before leaving the factory to ensure a plug-and-play experience.

What is the minimum order quantity for custom optical modules?

The minimum order quantity for light customization (such as specific parameter adjustment) is 10 pieces, the minimum order quantity for medium customization (such as function optimization) is 50 pieces, and the minimum order quantity for deep customization (such as new function development) is 100 pieces. Special circumstances can be negotiated, and we also provide small batch prototype development services to help customers verify the concept before purchasing in large quantities.

Do you offer custom solutions?

Yes, we tailor our solutions to meet the specific requirements of each client.

What is your pricing model?

Our pricing is flexible and depends on the scope and complexity of the project. Contact us for a detailed quote.

How can I track the progress of my project?

We provide regular updates and have a dedicated project management portal for clients to track progress.

Do you offer support after project completion?

Yes, we offer ongoing support and maintenance services to ensure your solution remains effective.

How to monitor the health status of optical modules?

All of our optical modules support digital diagnostic monitoring (DDM) to monitor key parameters such as temperature, voltage, optical transmit power, optical receive power, and laser bias current in real time. These data can be viewed through the network device command line or management system, or integrated into a third-party monitoring platform. We also provide optical network monitoring software that supports predictive maintenance and alarm functions.

How do I contact customer service?

You can reach our customer service team via email, phone, or live chat on our website.

Contact Us

Call

+86-18302784206

183 0278 4206

Address

3/F, Yunqi Technology Port, Guanggu, Hongshan District, Wuhan City, Hubei Province, China